Shifting Gears Part II: The EV Circular Economy and Alternatives

The global transition to electric vehicles (EV) has been supported as a critical component of combatting the climate crisis. By the year 2030, industry analysts predict there will be at least 145 million EVs on the road globally. However, the EV shift has led to serious environmental and human rights violations, putting the sustainability of the EV transition into question.

Manufacturing EVs is resource intensive and relies heavily on the mining industry. Transition minerals such as lithium, cobalt, nickel, manganese, and graphite are key ingredients in EV batteries. The demand for transition materials has dramatically increased the past few years and will continue to increase at an exponential rate in the coming years. For example, in 2022, the global demand for lithium exceeded supply despite a 180% increase in lithium production since 2017. The mining industry is notorious for extremely dangerous work conditions, violating Indigenous Peoples’ rights, and exploiting workers through the use of forced and child labor.

Additionally, EVs produce electronic waste which can further harm the environment. The average life of an EV battery is around ten years. Once they can no longer function in an EV, most batteries get thrown away and end up in landfills, where they produce toxic hazards. As it stands, the amount of electronic waste produced by EVs will exponentially grow as EV sales increase by the millions.

Drastic changes are needed for the EV transition to be more sustainable. A business model that prioritizes recycling and reuse and invests in technologies that limit mineral input is needed. Additionally, alternatives to EVs, such as greater investment in public transportation infrastructure, must be explored.

What is the Circular Economy?

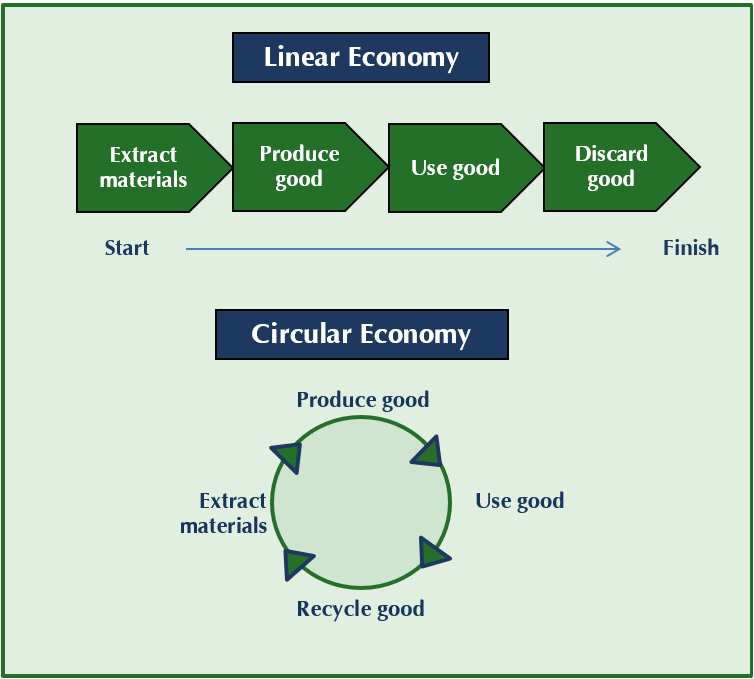

The circular economy refers to an industrial process that is restorative and regenerative. It ensures that resources maintain the highest possible value and prioritizes recycling and reusing. Essentially, a circular economy involves keeping materials and products in circulation until they can no longer be used. This process is different from the linear economy, sometimes referred to as the take-make-waste economy, where goods are discarded after a single use. For EVs, the circular economy involves reusing parts of vehicles, especially their batteries, and recycling the materials to extract valuable minerals like cobalt, lithium, nickel, and manganese.

Using EV batteries for other purposes once they can no longer be used in EVs is often referred to as a “second-life.” Better battery design could also allow third and fourth life cycles. New battery applications include mobile products, like RVs, electric forklifts, and boats, as well as stationary goods, like off-grid solar systems.

Why Circular Economy

Car companies and the US government have responded to heightened mineral demand needed for EV production by investing in the construction of new mines. Of these mines, around seventy-nine percent of lithium extraction sites “are located within 35 miles of Indigenous reservations.” These sites did not receive the free, prior, and informed consent (FPIC) from indigenous communities.

EV batteries also pose environmental risks throughout their life cycle. The production of EV batteries releases toxic fumes during the mining process. The refining process also creates toxic waste that contributes to water pollution. Once batteries are used and discarded, they become hazardous material, according to the UN. They can release toxins, dangerous heavy metals, and toxic fumes. This damages ecological systems and threatens the health of local communities, disproportionately impacting Indigenous communities and communities of color. Toxic fumes and runoffs from these mining sites frequently end up in the water sources that these communities use. Consequently, they experience higher risks of diabetes, birth defects, miscarriages, and cancer. Discarding EV batteries is also dangerous logistically. The cell structure combined with flammable materials creates a risk of thermal runaway that requires stringent safety measures to transport and discard them.

Adopting a circular economy would help diminish these negative human and environmental impacts. Recycling and reusing EV batteries, in addition to other materials used in autos, lowers the amount of waste ending up in landfills and decreases reliance on dangerous mining extraction. Research estimates that recycling EV batteries could provide 53% of lithium, 53% of nickel, 57% of manganese, and 60% of cobalt needed globally in 2040. This would decrease reliance on mining.

The positive environmental impacts of the circular economy are also significant. It is predicted that a circular economy can cut emissions by 56% by 2050. The Argonne National Laboratory found that using recycled battery materials reduces the amount of energy and emissions involved in battery production. Focusing on a circular economy, instead of shifting mining practices to the US, can drastically improve human rights and environmental conditions for vulnerable populations in the US and abroad.

It can also provide financial opportunities and benefits to auto companies. Financial studies show that circular business models are more profitable than traditional models. Some estimates show improved profitability “by as much as 1.5 times along the value chain.” By relying on recycled material, automakers will not need to invest as much in mining these products. Their production costs would decrease as they rely on cheaper, recycled materials. Expanding the life cycle of EV cars and batteries creates opportunities for revenue along the life cycle. For example, reusing EV batteries allows companies to enter new markets to sell their products instead of paying to dispose of them. As circularity becomes more popular, the economic benefits are predicted to grow even further.

Finally, reusing EV batteries and other parts extends the life of these goods by powering other products. Once EV batteries fall below 80% of their original capacity, they are no longer fit to power a vehicle. They can, however, be used to power other products, like forklifts and energy storage facilities. One company, called B2U, is using old EV batteries to power the electric grid in California. Reused EV batteries can power other goods we rely on in our daily lives.

EV Battery Life

Reusing and Recycling–What an EV Circular Economy Looks Like

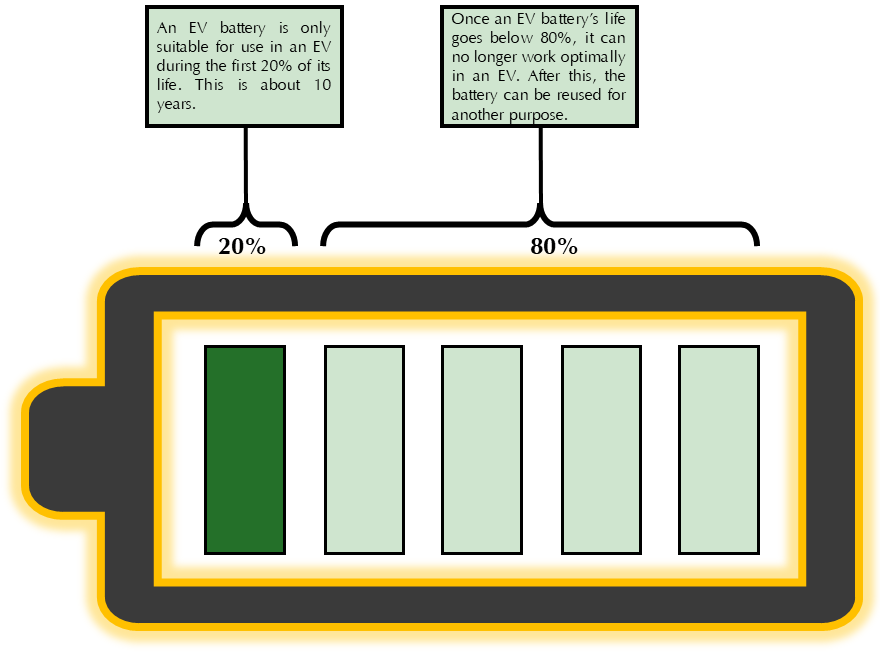

There are plenty of opportunities to reuse or recycle batteries, but there are unique challenges in doing so. An EV battery can only power an EV for the first 20 percent of its life; afterwards, the battery still contains 80 percent of energy that can be used elsewhere. Once a battery loses its capacity to operate EVs, it is difficult to analyze what state the battery is in and how much potential life it could still sustain. Despite this challenge, some companies are already designing technologies that measure battery levels in as little as two minutes.

https://www.ibcmitrovica.eu/inform/how-long-does-it-take-for-everyday-items-to-decompose/;

https://www.princeton.edu/news/2022/03/01/better-way-recycle-lithium-batteries-coming-soon-princeton-startup

There are plenty of opportunities to reuse or recycle batteries, but there are unique challenges in doing so. An EV battery can only power an EV for the first 20 percent of its life; afterwards, the battery still contains 80 percent of energy that can be used elsewhere. Once a battery loses its capacity to operate EVs, it is difficult to analyze what state the battery is in and how much potential life it could still sustain. Despite this challenge, some companies are already designing technologies that measure battery levels in as little as two minutes.

Once an EV battery can no longer be reused, the next phase in the circular economy is recycling it. Currently, less than 5% of EV batteries are recycled. Specialized companies, still relatively new in North America, recover valuable elements including cobalt, manganese, lithium, and nickel, from the battery cells. The recycling industry’s goal is to recover up to 95 percent of the most valuable metals, but they are only currently able to extract less than 50 percent. Effective recycling has the potential to reduce the global demand by 2040 for copper, lithium, cobalt, and nickel by 55 percent, 25 percent, and 35 percent, respectively.

Despite the benefits of recycling EV batteries, the process of doing so is quite complicated. At the moment, car batteries are not designed with the purpose of having their materials recycled. This makes it difficult to recycle them. New designs and innovations in EV batteries also means the recycling industry has to keep up and develop new strategies to break them down.

The recycle and reuse process can also apply to other parts of the electric vehicles, like metal components. The EV battery only represents about 40 percent of the vehicle’s value, which in total is made up of more than 30,000 parts.

While circular economies offer financial benefits, most of these only occur in long term projections. Creating a circular model has high upfront costs for companies. They must develop recycling facilities, invest in the science needed to recycle batteries, train personnel, and rethink their battery designs with disassembly in mind. The initial costs are large, and companies must be willing to jump over that barrier to reap economic benefits down the line.

The relative newness of EVs also poses a challenge. Societal pressure at the moment is pushing for vehicle electrification. The focus is less on the environmental and human rights impacts of EV development. Companies are not facing as much pressure to create circular models, so there is less incentive to do so. However, as the EV transition advances, more awareness of its impact will emerge, and companies will have to respond.

Another obstacle is the lack of uniformity in the industry. Battery designs are constantly changing. This forces recycling and reusing operations to continuously redevelop as a result. Instead of standardizing the technology, companies are competing to create the newest and best batteries and EVs. Uniform policy is needed at a federal level to help regulate the way in which these parts are designed, which directly impacts end of battery life solutions.

Alternative Solutions

The circular economy offers helpful solutions to some of the major concerns in EV development. However, some critics say that more systemic changes need to be made than incorporating a circular economy. Since the EV transition is rife with human rights and environmental concerns, these critics offer solutions that decrease reliance on the construction of personal-use EVs and vehicle use more broadly.

A popular alternative strategy involves reducing the use of personal-use vehicles. Studies show that “our use of cars today is extremely inefficient–the vast majority of cars are owned and operated by a single household, and this results in overcapacity: five-seat cars used mostly for one-passenger trips, and vehicles that are stationary 92% of the time.”

Private companies, policymakers, and citizens should push for tools that create better access to public transportation, walking, and bicycling. A quarter of all global CO2 emissions come from transportation. In addition to the environmental benefits, creating better access to public transportation would create millions of jobs globally and create equity to transportation services for the many low-income households who do not own personal vehicles. Several cities have even invested in the electrification of their public transportation systems. Car sharing could also decrease the use of privately-owned cars and expand transportation access. This solution would need to go beyond ride sharing services like Lyft or Uber and create a system used by significantly more people to see results.

As we continue to use single-use vehicles, it is imperative that vehicles are designed more efficiently . Some advocates recommend making cars smaller so they use less material in their production. Another tactic is to encourage battery design that relies less on mineral inputs. Lithium-ion batteries are the predominant battery design used in EVs. Additionally, battery technology can increase the life of batteries, reducing the amount of e-waste and decreasing the demand for replacement.

Conclusion

Companies must act now to ensure that the EV transition is sustainable, just, and equitable. The current EV industry is filled with human rights and environmental issues, especially in mining and extraction. Adopting a circular economy could help reduce the reliance on transition minerals and, as a consequence, decrease the amount of violations that occur in the industry. Investing in reusing and recycling is crucial to create a sustainable practice. Other alternatives, like public transportation and reducing the mineral inputs needed in EV batteries, also provide opportunities to address the concerns related to the EV transition. Ultimately, companies have the power and resources to ensure the EV transition is itself sustainable.